Tashya specializes in Embedded Hardware Board Design services, offering expertise in designing boards with microprocessors, microcontrollers, DSP, and programmable modules. Our development process encompasses multilayer PCB layout, thorough analysis of signal and power integrity, and other critical aspects. With a seasoned team, we bring extensive experience to the table in designing, verifying, and validating complex digital designs. Our commitment is to support clients in bringing their ideas to life through rapid prototyping.

- Requirement Analysis: This is the initial phase where the client's requirements are gathered and analyzed. It involves understanding the purpose, functionality, specifications, constraints, and target market for the embedded hardware.

- System Design: In this stage, the overall system architecture is defined. It includes selecting the appropriate microcontroller or microprocessor, determining the necessary peripherals, designing the hardware interfaces, and establishing communication protocols

- Schematic Design: Engineers create detailed schematics that depict the interconnections between components, specifying the electrical connections and components used in the hardware.

- PCB Layout Design: This phase involves converting the schematic into a physical layout. Designers place the components on the PCB (Printed Circuit Board) and create the traces to establish connections between them, considering factors like signal integrity, power distribution, and electromagnetic interference.

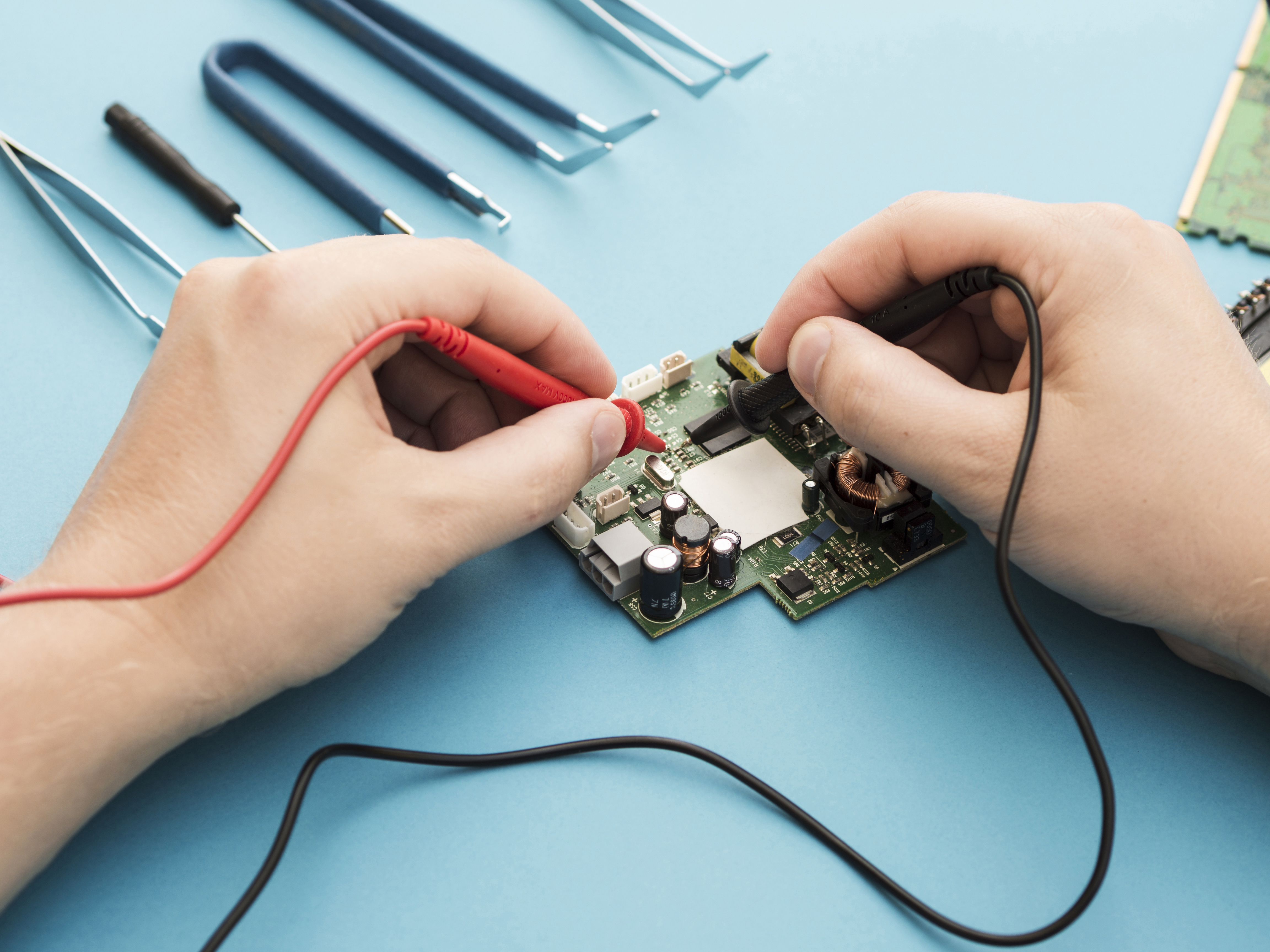

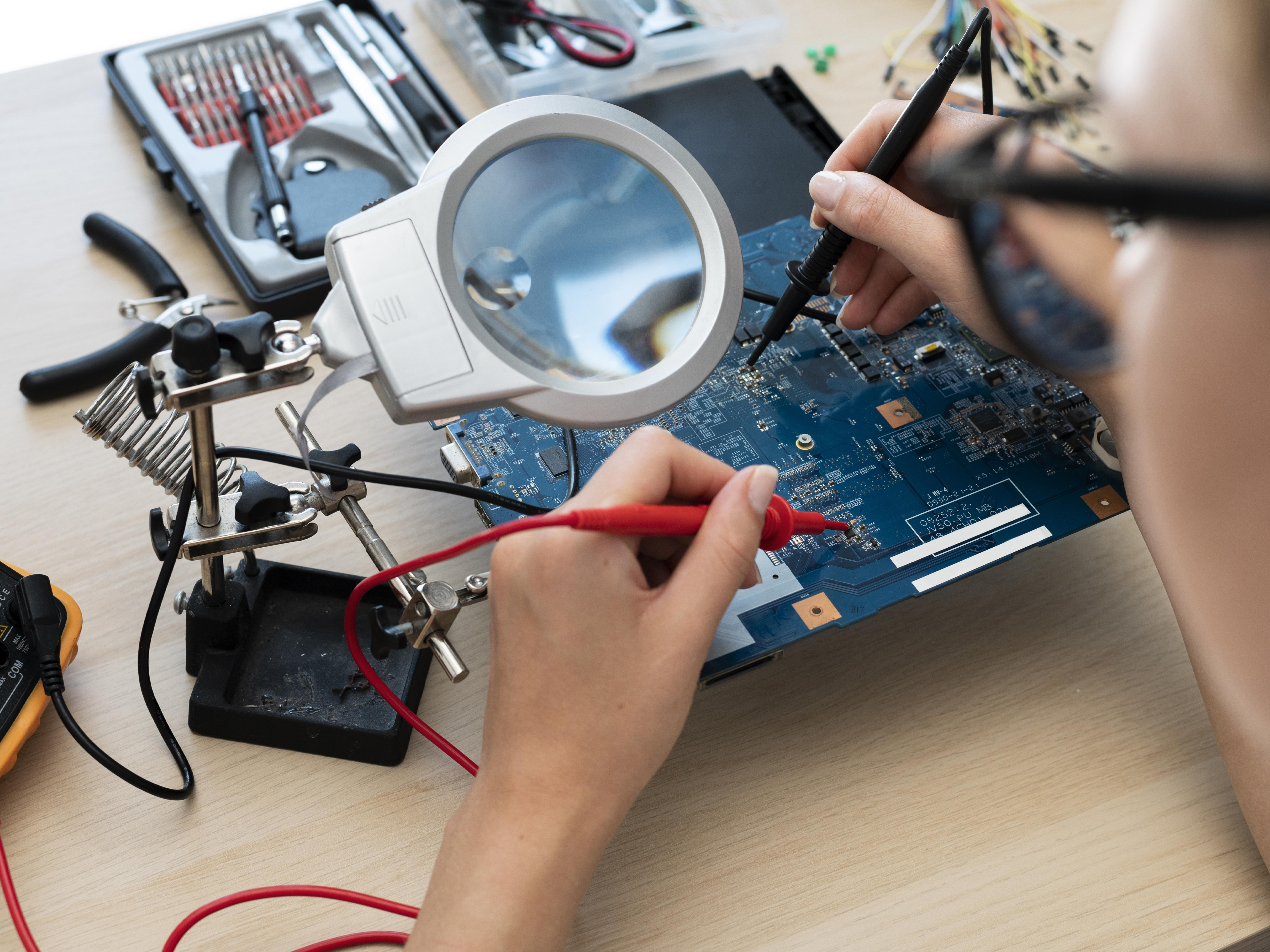

- Prototype Development: Once the PCB layout is complete, prototypes are manufactured. This stage involves assembling the components onto the PCB and conducting initial tests to ensure functionality.

- Testing and Verification: The prototype undergoes rigorous testing to verify that it meets the specified requirements. This includes functional testing, performance evaluation, reliability testing, and compliance with industry standards.

- Refinement and Optimization: Based on the test results, necessary refinements and optimizations are made to improve the design's performance, reliability, and efficiency

- Production Preparation: Once the design is finalized, it's prepared for mass production. This involves creating manufacturing documents, selecting vendors, ensuring supply chain readiness, and optimizing for cost-effective production.

- Manufacturing and Deployment: The hardware design is sent for mass production, where PCBs are manufactured, components are assembled, and quality control measures are implemented. Post-production, the hardware is deployed for its intended purpose.

- Maintenance and Support: After deployment, ongoing maintenance and support services might be provided to address any issues, release updates, or provide technical assistance.

These stages can vary in complexity and might overlap or iterate based on the project's requirements, but they generally encompass the key phases involved in embedded hardware design services.